The GTWSB submersible mixers impressively demonstrate their strengths even with viscous media in continuous use in biogas plants. The safety devices of the GTWSI -EX agitator guarantee protection against explosions in the vicinity of flammable gases with increased danger areas, such as fermenters and containers with changing fill levels.

Due to the energy efficiency class IE5 of the GTWSB 206-E drive, the biogas industry, end customers and plant builders in Germany have state subsidies at their disposal, because the submersible motor of the agitator ensures considerable energy savings during operation.

Features:

- Approved for EX protection zones 1 & 2 (GTWSI-EX)

- Three-phase motor with built-in thermal contacts

- Sealing probe in the oil chamber, control lamp on the switch / control

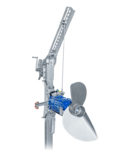

- Stainless steel slide, optionally with socket pin or pin guide

- Stainless steel propeller

- Electric cable with protective hose